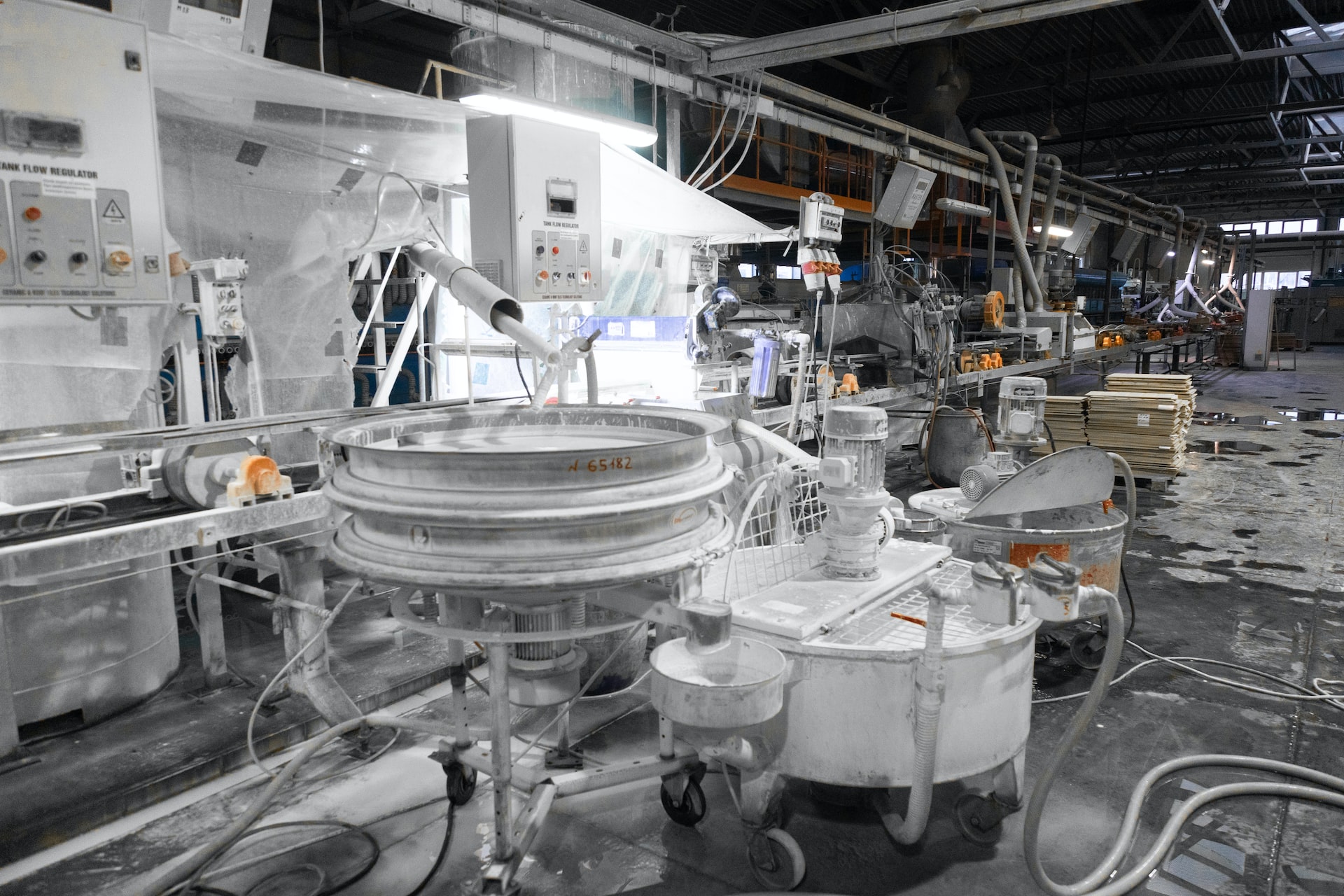

Everything You Need to Know About Industrial Blenders

When choosing an industrial blender, knowing what you need to consider before making a purchase is essential. Learn about the available materials, including stainless steel, glass, copolyester, and electronic controls. A blender can be used to make a variety of products, including dry pet food.

Glass

There are several advantages of industrial glass blenders over plastic blenders:

- Glass blenders are less likely to crack from frequent use, which makes them a more durable choice in the long run.

- Glass jars are more resistant to extreme temperatures.

- Unlike plastic jars, glass retains its clarity and resists odors.

Plastic jars, on the other hand, tend to absorb food odors and are challenging to clean.

Another significant advantage is that glass jars are easy to view, making it easy to check the consistency of the finished product. This is especially helpful when making baby food or ultra-smooth drinks.

Copolyester

The High Power Blender is an ultra heavy-duty blender with a 64-ounce copolyester container and a 3.5-horsepower commercial motor. It has dual pulse and speed settings and a dishwasher-safe copolyester container. It comes with a BPA-free lid and cap and a high-impact stainless-steel blade. It is an excellent choice for commercial kitchens. It can handle many workloads simultaneously while blending large amounts of material.

Another essential feature of a copolyester jar is its durability. This material is more robust and lighter than glass and can withstand knocks. It is also resistant to ice cube crush. This feature makes it perfect for blending ingredients such as fruits and vegetables. The Raptor(r) 64-ounce container is dishwasher-safe and stackable, with a removable clear cap for easy access to ingredients.

Programmable Units

Industrial blenders with programmable units allow the user to customize specific blending characteristics. For example, a user can modify the speed of the blades according to the desired operation time. This feature can help create complex blending sequences. It also allows the user to modify the duration of the blending process.

Programmable units can also be used for storing and recalling specific settings, such as motor speed and operating interval. Programmable blenders typically read information encoded on a plastic card inserted into the blender’s memory. The programmable feature makes it easier to create customized drinks. Besides ensuring consistency, some programmable units include colored containers for separating ingredients. They may also include an aerating disc, which incorporates air into the blend.

Power

Industrial blenders come in different power ratings. Each power rating measures a different aspect of the machine’s performance. Choosing the correct power rating is critical for efficient blending. While the higher horsepower rating is better for quick bursts of power, wattage is better for continuous power. The highest wattage may be the best choice if you’re blending many materials.

The control panel is an integral part of industrial blenders. These control panels determine the amount of input required to operate the blender. Industrial blenders have become increasingly sophisticated with the advent of programmable logic controllers. These controllers are also often custom-programmed for each application.

Torque

Industrial blenders are used for mixing a variety of products. They can handle wet and dry ingredients and can be controlled at various speeds. The blades of an industrial blender are usually sharper than the ones on a standard blender. Some models also have two different speed settings and multiple modes..

When selecting a commercial blender, choosing the correct motor for the task is essential. The suitable motor should deliver the desired torque without compromising efficiency. The output torque of a blender machine is directly related to the speed of the machine. The blade speed can significantly alter the torque, and the maximum speed depends on the number of blades. The motor’s speed limit and back EMF are also factors that influence torque.